It is possible to paint the car body, walls of the house or whiten the ceiling in two ways: long and poor quality - manually, or quickly and beautifully, but using a spray gun. Here are just today's models have little in common with plastic nozzles for vacuum cleaners, which were used by our parents. Modern spray guns have become much more convenient, productive and more diverse. We will figure out how to choose the right equipment that will cope with repairs in the house or work in a car repair shop.

Content:

The best manufacturers of spray guns - which company to choose

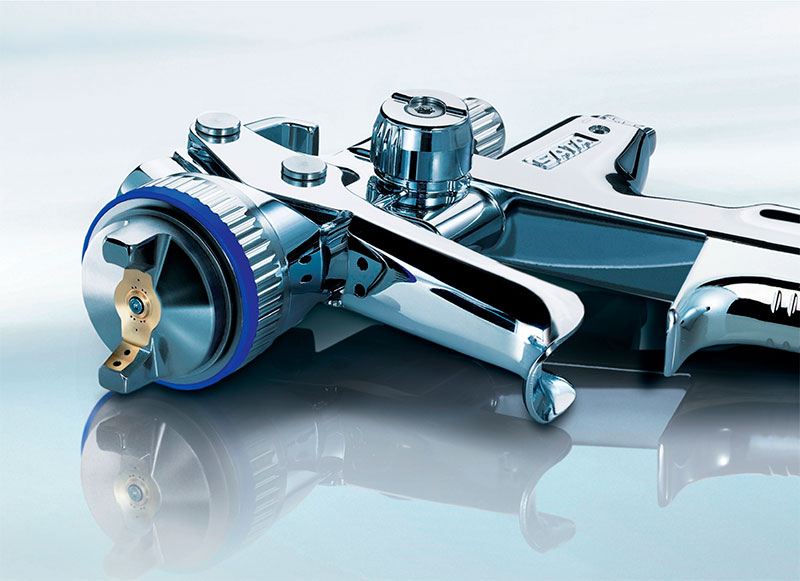

If you are looking for a reliable and durable spray gun, feel free to take the modern models of well-known companies that produce highly specialized equipment for professionals.

There are several recognized leaders who offer truly quality products:

1. Sata

2. Walcom

3. Devibiss

4. Wagner

5. Bosh

You can learn more about the products of these manufacturers in our ranking of the best spray guns, and even choose one of the considered models, if you do not have time for a thoughtful study of the characteristics. But it is better to carve out 10 minutes and find out how to find a spray gun that will meet your requirements.

The device and the principle of operation of the spray gun

The gun has a fairly simple design and consists of only a few basic blocks:

- Spray gun;

- Paint tank;

- Pressure regulator;

- Nozzle and filter for paint;

- Air head.

Also, depending on the model, the spray gun may be supplied (or purchased separately): a compressor with a receiver or an electric pump, a battery, or an ordinary power cord with a plug.

Despite some structural differences, all sprayers do one job: blow out paintwork materials from the built-in tank or external container with a continuous cloud of spray. This is the responsibility of the compressor or the airbrush pump, which squeezes the emulsion through a nozzle under high pressure.

Inside the gun there are two separate channels: the air valve is closed, and intended for paint - with a special needle, in the literal sense, blocking the nozzle from the inside. When you pull the trigger first starts out compressed gas. When you drown the lever deeper, the needle will move, releasing the paint in the nozzle. Here the emulsion mixes with the air flying out under pressure, and you immediately get a cloud of a certain dye, a so-called torch.

Having released the trigger, you cease to hold the needle in the open position, and the spring installed inside immediately returns it to its place. Only then is the air supply shut off. With this solution, even the first and last “spots” of paint will fall flat on the surface - without drops and drips.

Types of spray guns

Mechanical

The weakest in the whole family, they are not distinguished by any particular accuracy or speed of painting. But their cost is much lower than on any other models, so for simple tasks like whitewash they are used quite often. Mechanics work on the principle of the most ordinary pumping chamber (as in a children's water gun). By pressing the trigger several times, you force air inside. And as soon as the pressure reaches 0.4-0.6 MPa, the valve will open and the paint will begin to exit through the nozzle.

Pros:

- The simplest design;

- Paint fairly evenly;

- Do not require special skills in the work;

- Very low cost.

Minuses:

- The need to constantly pump air manually;

- A large percentage of the dispersion of the suspension.

Pneumatic

Such spray guns are usually made from light but durable aluminum. They qualitatively, though not always economically, distribute paintwork materials over the surface: the percentage of emulsion transfer varies from 45 to 70% depending on the model - the rest of the paint is dispersed in the form of fog.

The main work here is performed by a compressor that supplies compressed air to the gun. It is able to create pressure from 0.7 to 2 bar at a gas flow rate from 150 to 1000 l / min. Pneumatic spray guns can have both a built-in tank with a volume of 0.5-2 liters, and an external one - connected through a hose. In the second case, the capacity for paint is increased to 25 liters in models for home use and up to 600, if we are talking about professional equipment.

Pros:

- High speed and excellent quality of painting;

- The ability to use external tanks of very large volume;

- Work with any paintwork materials;

- Simple and easy to maintain.

Minuses:

- This is a professional technique, and it is not cheap;

- The average percentage loss of paint at the exit.

Electric Air Spray Guns

These spray paintwork materials are no longer under compressed air pressure, but with a pump. Such a device works from a normal 220V network. Electric spray guns are compact, easily disassembled and assembled, do not create problems during maintenance. All these advantages make vozdushki very popular with home craftsmen.

The weight of the device with an empty tank is from 1.4 to 2.5 kg, up to 1 l of paint can be placed in the built-in container - that is, it is fairly comfortable to hold the spray gun on weight. But the quality of the transfer of such devices is somewhat lower than that of pneumatics. But good power and performance (about 0.35 l / min) make them indispensable for home use.

Pros:

- Portability and light weight;

- Easy maintenance;

- Large selection of nozzles included;

- Good performance;

- Low cost.

Minuses:

- Noisy work;

- The quality of painting is lower than that of pneumatic sprayers.

Electric plunger (airless) spray guns

In such models, the emulsion pushes out a special piston - a plunger. The quality of painting here will not be the best, however, due to the lack of air blowing, the formation of "fog" and the mixture consumption will noticeably decrease.

As a rule, airless spray gun is a compact device that has a tank with a capacity of 0.8-1.2 liters. The feed rate of paintwork materials in “home” and professional models can vary between 0.3–30 l / min, which allows you to choose the right machine for any amount of work. But the main thing - plunger devices are able to suck out paint directly from a bucket or can through a special hose.

Pros:

- Lightweight and comfortable to use;

- Easy to clean;

- Sufficient performance;

- Economical paint consumption;

- Reasonable price.

Minuses:

- Low quality painting;

- You can use only acrylic and synthetic coatings.

Rechargeable

In fact, these are the same electrical models, only they do not work from the network, but by charging the battery. In appearance, the spray gun resembles a manual screwdriver - just as convenient and compact. The device is additionally equipped with a tank with a capacity of 1-2 liters, while the indicators of power and performance of it almost do not differ from the characteristics of electric airways.

Pros:

- Compact size;

- Easy to use;

- Many complete attachments;

- Good quality painting, but not perfect.

Minuses:

- It is necessary to periodically charge;

- The average quality of painting;

- The cost is higher than conventional electric models.

Spray gun selection options

Gun type

In electric models, the gun is balanced with a motor, so there is nothing special to advise. In pneumatic devices, the situation is somewhat different - the working nozzle must be selected independently.

There are 3 possible options:

1. HP (high pressure)

Pistols of this design allow you to paint any surface very quickly. Working air pressure with a relatively small flow rate reaches 5-6 bar, and the percentage of paint loss does not exceed 50%.These guns are cheap and easy to maintain, but the quality of the coating they are not the best.

2. HVLP

They work under low pressure with increased air flow, which allows transferring up to 65% of paint to the surface. The working gas in the apparatus is supplied under high pressure, after which a vacuum occurs, and at the outlet its pressure barely reaches 1 bar. The quality of painting remains good due to the stable torch, and the speed of work does not fall, which is why such guns are considered the most effective.

3. LVLP

Use a small amount of air and create a low pressure. Due to this, they have a minimum percentage of paint loss (up to 20%). Pneumoguns provide excellent quality of painting and are not too demanding on the performance of the compressor - 200 l / min is enough for their work. But cost LVLP dearly.

Power (for electric models)

Sprays with a capacity of up to 500 W can be attributed to domestic. They do not differ in the ideal quality of painting, they often give an uneven layer and do not cope well with thick undiluted compositions. But such models are very cheap, and so much so that sometimes they are bought for one-time work.

Models with a capacity of over 500 watts are already professional. Such devices are capable of perfectly and evenly covering the surface with layers of paint, regardless of its thickness.

But the power of pneumatics directly depends on the compressor used and can be from 0.7 to 3 kW. The most running characteristics are 1.2-1.8 kW. Also here you need to take into account the volume of the receiver, since it is he who determines the performance of the device. 24-50 liters will be enough for homework, professionals from large sites will need from 100 to 500.

Pressure

1. High (up to 5-6 atmospheres) - allows you to quickly treat any surface, but it gives a large percentage of paint loss. But the quality of the coating will be excellent.

2. Average (4-6 atmospheres) is the best choice. With this pressure, you can work with virtually any paint and varnish and get consistently good quality staining.

3. Low (2-2.5 atmospheres) - gives not the most ideal coating, but allows to reduce paint loss to a minimum of 20%.

Attachments (tanks, nozzles)

Paint tanks mounted directly on the gun may be located above or below. The first ones are always lightweight and made of plastic or nylon. Their volume does not exceed one liter, but you will have to get used to working with such a device because of the shifted center of gravity. The tanks located below are usually more spacious and are made of metal.

The nozzles in the spray guns can have an outlet diameter of 1 to 3 mm, of which the most popular are nozzles with openings of 1.4-1.7 mm. If you plan to use equipment for applying liquid mortars (for example, putty), you will need a model with complete nozzles for 6-7 mm, or they will have to be purchased separately.

Which spray gun to choose

1. If you need a spray gun for one-time work, and the quality of the coating is not critical (for example, when whitewashing), you can take the simplest mechanical spray gun. For a more economical consumption of paintwork materials, a plunger device is suitable.

2. In a big house, where you often have to paint something, it is better to use an electric air spray gun. The quality of his application is quite good, and it is easy to take care of such a technique. And most importantly - this device works from a normal power supply.

3. For professionals who work with varnishes and paints every day (car painters, finishers, carpenters), pneumatics with an external tank and a good HVLP or LVLP gun, giving a stable torch.

4. If you have to work with the spray gun in a tight space and on a relatively small area, take the battery model with good autonomy - it should last for at least an hour on one charge.

Cost of spray guns

1. Pneumatic spray gun costs from 600 to 40,000 rubles - depending on the manufacturer, type of gun and the presence of various adjustments.

2. Electric air model can be bought at a price of from 1500 to 6000 rubles.

3. Plunger devices are in the same price category: 1700-5500 rubles.

4. The battery device will pull 5-10 thousand.

5. Mechanics can be taken for 800 rubles.

It will be interesting to friends too