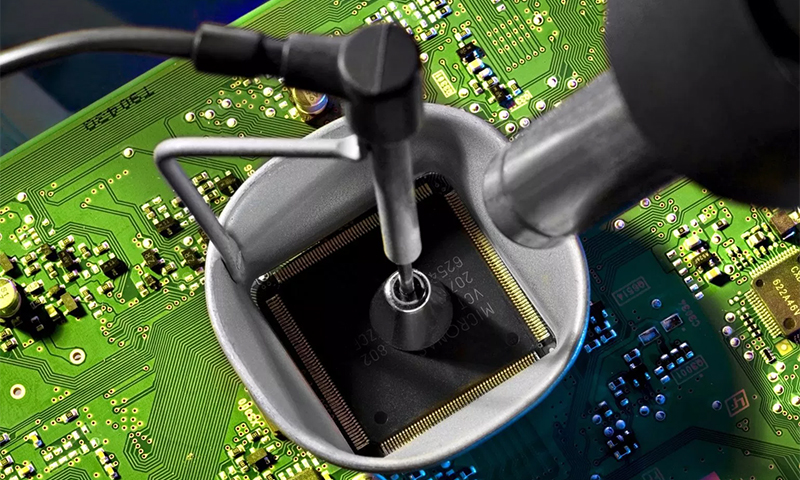

A compact device representing a failure of a prefabricated structure of a fan, a heating element, a common body, and a nozzle. Powered by a single-phase 220 volt power supply. Most often, the soldering dryer works as part of the station, along with the control-controlling unit. The heat block is used for local heating of the place of soldering, melting of materials with a low melting point: plastics, polymers, tin, lead, bismuth and alloys based on low-melting metals. The maximum air flow can reach a temperature of 400 ~ 600 ° C. Selection criteria: exhaust temperature, flow rate, mass flow.

Content:

- ELEMENT 858D - from inexpensive

- BAKU BK-8032A ++ - with microprocessor

- ZUBR 55350 - an inexpensive professional

- YIHUA 8858 - soldering air wagon

- Yaxun YX-8032 - protection against static electricity

- Lukey 702 - a budget option

- Quick 857DW + - four additional tips

- Weller WHA 900 Set - Professional Class

ELEMENT 858D - from inexpensive

Hand tool with almost instant warming up. The device reaches the working temperature for a period of less than one second. The possibility of changing the thermal range. It works with various types of microcircuit cases, preheating the contacts to the required temperature.

Easily melts plastic, polymers. Melt alloys based on low-melting metals. It has a constant heated heat flux with adjustable mass flow.

Pros:

- Compact, light weight.

- Comfortable handle made of pleasant material, clear and easy adjustment.

- Cost, is completed with nozzles.

Minuses:

- Thermal overheating protection would be useful.

BAKU BK-8032A ++ - with microprocessor

Soldering dryer with integrated microprocessor based remote control. The electronic system allows you to adjust the degree of heating, to increase or decrease the mass flow rate of air. There is a function to return to the original parameters.

The displayed data is visualized on a digital display. The heating element is designed as a spiral. Turbine type air blower. Food - single-phase stationary power grid 220 volts. Airflow range 0 ~ 30 l / min. Heating the gas-air mixture to 480 ° C.

Pros:

- Compact light heat gun.

- Fast and efficient heating.

- The price, clear and simple management.

Minuses:

- With prolonged work at peak temperatures, the handle is noticeably heated.

ZUBR 55350 - an inexpensive professional

Professional grade hot air gun. It is used for dismantling electronic radio elements or soldering in a non-contact manner. Heating the air flow to a temperature of 500 ° C occurs in a fraction of a second.

Localization of the heating site is carried out by three interchangeable nozzles with a different diameter of the output nozzle. Provides an economical standby mode with temporary interruptions. The device has the ability to adjust the mass air flow, reaching at a maximum of 120 l / min.

Pros:

- Easy, convenient to use. Ergonomic handle with anti-slip coating.

- Decent mass air flow, the possibility of smooth adjustment.

- Price, electronic control, display.

Minuses:

- No negative reviews.

YIHUA 8858 - soldering air wagon

Thermo-air heating dryer. It is used for soldering radio elements in a contactless way, heating plastic phone cases, heating electronic circuit boards. It performs the role of glue thermogun for melting polyethylene rods while fixing different parts with each other.

It is very convenient when working with heat shrinkable tubes for connecting electrical wires. Used turbine fan. Heater - ceramics and ferroalloy.Provides a function of automatic blowing at a temporary break and the location of the hair dryer on the stand.

Pros:

- Ergonomic handle, compact, light weight.

- Replaceable nozzles, the choice of blowing mode.

- Autoblow, "sleep" mode at the break, evrovilka.

Minuses:

- A rare type of attachment of nozzles - bayonet. Coarse finish welds hull.

Yaxun YX-8032 - protection against static electricity

Compact device for working with electronic boards, dismantling plastic housings, heating soldering elements. Built-in static protection function. It is completed with several nozzles with a different diameter of the output nozzle.

Designed for use with multiple voltage parameters in a stationary power network: 100, 110, 220 volts. It is possible to smoothly change the mass air flow. The heated flow range is 100 ~ 420 ° C. There is a support for the location of the device at the time of the break.

Pros:

- Very comfortable, practical, small, light.

- High-quality heating and localization of the heating zone, thanks to the nozzles.

- Good quality, easy to operate.

Minuses:

- Expensive, but functional justifies the cost.

Lukey 702 - a budget option

Soldering dryer, which is part of the station of the same name, equipped with a classic soldering iron and a control unit. Smooth adjustment by a mass stream of air is provided. There is a function of exhibiting the required temperature.

The arrangement of the turbine type compressor in the handle allowed saving space, reducing the overall dimensions of the apparatus, and improving internal thermodynamics. Significantly reduced sound produced by the supercharger. Sleep mode is automatically enabled when the device is placed on a stand.

Pros:

- Wide functionality, the presence of a typical soldering iron.

- Performance, temperature range.

- Price for such technical capabilities.

Minuses:

- Moves with temperature, needs to be calibrated. At first glance, the design is flimsy.

Quick 857DW + - four additional tips

Thermogun equipped with a diaphragm type compressor. Designed to work with sensitive electronic components and boards.

The device is completed with four nozzles for localization of the place of heating and increase of thermal efficiency. Nichrome heater is used. The current status is signaled by LED indicators and a display.

Pros:

- Advanced functionality, four interchangeable nozzles.

- Reliability, performance.

- Intuitive and simple control panel.

Minuses:

- Requires calibration.

Weller WHA 900 Set - Professional Class

Professional-grade analog soldering iron. Built-in features for smooth adjustment of hot air flow and temperature change. Thermal range 50 ~ 550 ° C. Turbine type supercharger.

A wide range of special nozzles are available that localize the heating zone and increase the heating efficiency. The device is made in the antistatic version, which prevents damage to the processed electronic board.

Pros:

- Workmanship, exhibition accuracy of flow and temperature levels.

- The wide nomenclature of replaceable nozzles.

- Power, performance.

Minuses:

- Perhaps the price. But this is a professional machine.

It will be interesting to friends too