During the repair often raises the question of finishing floors. Expensive coating materials, such as cork, parquet or carpet, are not always affordable. The tile very much cools the room and is suitable only for a bathroom and a toilet. Laminate is afraid of water and may deteriorate if used carelessly. Unlike all of these types, linoleum has a moderate cost, retains heat, moisture resistant and is designed for 25 years of service. A simple method of installation allows you to perform all the work yourself and save on installation. But what are the types of linoleum and what are their key characteristics? Understanding these details will help you find the perfect coverage for a particular room.

Content:

The best companies for the production of linoleum

High-quality floor products are produced by both domestic and foreign factories. If you don’t have time to research the features and differences of linoleum and just want to quickly get excellent products for many years, then you should choose among the products of these manufacturers:

- Armstrong;

- Grabo;

- Juteks;

- Tarkett;

- Forbo.

But if you want to delve into not only the parameters of the material, but also to get acquainted with specific models for different rooms, then you can read a detailed article.top linoleum manufacturers.

The structure and application of linoleum

Linoleum is widely known for its versatility in use in various institutions and private housing. This is a relatively cheap material that does not crack with time, and its installation is quick and easy.

Linoleum can be of different origin depending on the substances used in its creation, but most of the models have a similar structure of six layers:

- The foundation. It may be from a textile or foamed substance. Responsible for heat and sound insulation properties, as well as canvas flexibility.

- Fiberglass It adjoins directly to the base and is responsible for the strength of the entire material. It can be reinforced or ordinary.

- The basis of printing. To apply a beautiful and clear pattern requires a layer that absorbs the paint well and does not allow it to spread.

- Surface embossing. It is carried out on a layer for printing and additionally adds expressiveness to the drawing.

- Protective layer. It can be made of various polymers and plays the main role in preventing abrasion of the pattern and the material itself.

- The last material that gives shine to the coating and serves as an additional protection is a layer of PVC.

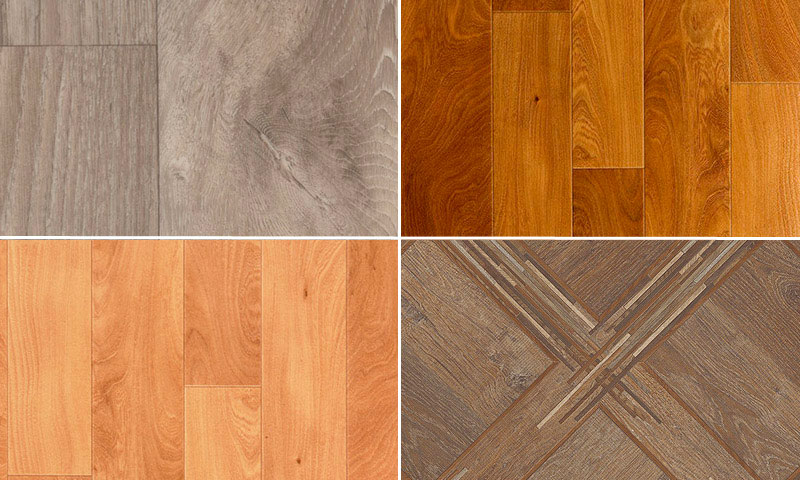

This multi-layered and inexpensive material can have a different pattern and embossing, which makes it possible to reproduce the look of natural wood on its surface. An inexperienced user may even confuse it with parquet or laminate. The palette of shades facilitates the choice of material for any interior.

Floor covering can be:

- without base (in the form of several layers of basic substances) on which the applied pattern is kept for a long time;

- from foam material that gives high moisture resistance and flexibility;

- from a fabric component that provides long service life and high quality.

A distinctive feature of linoleum is its moisture resistance. At the core of the product there are no absorbing layers prone to swelling, and reliable protective coatings completely exclude this possibility. Due to such properties, it is an indispensable material for the kitchen, bath, corridors with high traffic and frequent wet cleaning.Linoleum is made in various thicknesses, which gives high rates of heat preservation and insulation from sounds. This allows you to lay it in children's rooms and schools.

The popularity of linoleum gives and simple installation, which saves the family. The rolls are rolled and cut with a room size margin. After giving them time to finish off a bit, the floor is prepared: the garbage is removed, the gaps are filled up and the baseboard is dismantled. After which the laying and fasteners. This may be glue in the case of concrete floors or nails and strips for a wooden base (planks). The final stage is cutting off excess areas and fixing the plinth.

Varieties of linoleum

Manufacturers produce many types of linoleum differing not only in design and color, but also in the substances involved in its manufacture. This affects the application of the material and its cost.

Natural linoleum

Excellent material from natural ingredients worth good money. This is exactly what a floor covering is known as natural linoleum. Since the demand for it is not so great, to find such products on sale is more difficult. This material will be the ideal solution for allergies and asthmatics, since natural substances will not irritate the mucous membranes and respiratory organs.

Natural linoleum is made from jute fabric as a base. The filling layers are wood and cork flour. Pine resin acts as a binding component, and it is dyed with limestone powder and natural pigment substances.

Advantages:

- ecologically safe;

- many colors;

- resistant outer layer;

- easy to clean;

- does not deform from heat and ultraviolet;

- not subject to burning (if you drop a burning match in the kitchen, there will be no trace);

- prevents the formation of bacteria under it.

Disadvantages:

- expensive;

- in rooms with constant spray is not desirable;

- may break on throwing in the warehouse;

- brittle on bending, which requires very careful installation.

PVC linoleum

Treats the most widespread types. It has a textile or foamed base. Can be produced with a large range of thickness. The outer layer of polymer film well protects the pattern and texture from abrasion. The material has a large selection of colors and an affordable price. Let's apply to the nursery and a bedroom, office corridors, hospitals, schools and other institutions.

Advantages:

- does not transmit cold from concrete to the room;

- very simple styling technology;

- does not accumulate electricity and does not attract small garbage;

- a large selection of colors, patterns and sizes;

- ecologically safe;

- the material does not rot in wet conditions and is designed for 15-20 years of operation;

- affordable cost.

Disadvantages:

- may deform from high temperatures;

- chemical traces remain;

- on cold floors it loses elasticity and cracks are possible;

- over time, diverges at the joints due to the internal structure.

PVC linoleum is called synthetic and is divided into three categories of use. The household product segment is cheap, has a short lifespan (5-10 years) and is not very thick. Semi-commercial options are used in public buildings with little traffic and are designed for 10-20 years. Often it is purchased in the apartment. Commercial products are distinguished by high cost and wear resistance. A thick layer and additional protective coatings allow it to be laid in offices and workrooms.

Additional types of linoleum

In addition to the main two types, there are additional types of linoleum with specific components, but it is much more difficult to find them for sale. One of them is relin. Rubber-like material is well suited for wet conditions (changing rooms of gyms with showers, bathrooms, sanitary facilities). The product has two layers: hard bottom (bitumen) and smooth with a touch of the top. Advantage is resistance to water and flexibility, and the disadvantage is the presence of volatile substances with an unpleasant odor.

Glyphthalic linoleum has a fabric base and filler with coloring substances. Its binding component is an alkyd resin. The product has a persistent pattern and heat insulation. Excellent smoothing vibrations. Among the shortcomings - it quickly breaks at the bends, which complicates the installation. Great for children's room.

A colloxylin product combines nitrocellulose and a dye. It has no basis, therefore it is much thinner than analogues. It is resistant to water, glossy surface and flexibility, but tends to deform when temperature changes and shrinks with time. Can only be used in private housing, for example, in the bedroom.

Linoleum selection parameters

Despite the large variety of materials used in the manufacture of linoleum, there are many parameters inherent in all types of this product. Understanding these features, you can quickly determine the choice of flooring for specific conditions.

Used base view

Baseless linoleum options are quite thin, which reduces their insulating properties. But drawing at the same time permeates the entire thickness of the product. Therefore, erasing the upper layer will not lead to empty places in the part of the coating that is more walkable. Therefore, this product should be used in public places with low traffic (offices, offices). It is suitable for the hall in the apartment.

Polyurethane foam gives a high layer and good heat retention. Moderate flexibility facilitates installation. This type of linoleum is suitable for most children's rooms, kitchens and bedrooms. The fabric base will allow the material to be used for a long time, which is applicable in schools and hospitals with high traffic. Also this type is used in industrial shops and factories where there are no hard cutting objects in circulation. The workers have a warm surface under their feet, remaining solid and beautiful for a long time.

Material thickness

Linoleum can be of various thickness from 1.1 to 3.2 mm. Insulating properties and walking comfort depend on it. Therefore, in a children's room, where there will be a lot of noise and a warm floor is needed, a maximum thickness of 2.8-3.2 mm is suitable. The same thickness indicator should be chosen in the case of high-passable places, and for the office there will be enough material layer of 1.2 - 1.6 mm.

Wear resistance

This parameter indicates the service life of the coating. The thicker the protective layer, the longer the integrity of the pattern and the uniformity of color will be maintained, regardless of the number of passes through the material per day. The protective layer is specified in mm and can vary from 0.15 to 0.8 mm. For a private house or apartment, an indicator of 0.2–0.3 mm (in the entrance hall and kitchen) and 0.15 mm for a bedroom are sufficient, but in educational institutions a value of 0.4–0.5 mm is needed.

Moisture resistance

This parameter is not prescribed separately, but the material characteristics are evident from the substances in its composition. For the kitchen and bath, where there is the highest humidity, all types of PVC linoleum are suitable, as well as relin with a two-layer structure. Fabric types and baseless are best laid in dry rooms (bedroom, offices).

Roll width

Regardless of the type of linoleum, you should pay attention to the presence of a roll width corresponding to the parameters of the room. If the room has an area of 3 x 4 m, then it is worth looking for variants of rolls with a width of 3 or 4 m. This will allow you to put a solid sheet. Otherwise, joints will be required that may diverge over time. Rolls are 2.5-4 meters, but possible intermediate options depend on the specific type of product.

Classification and labeling

Two values are always indicated on the product: the first digit is the purpose of the premises, and the second is the class of the terrain. The indicator of room 1-2 is suitable for living rooms, and the numbers 3-4 should be searched for stacking in office and industrial buildings. The patency class combines many factors and forms a single maximum indicator. For example, for a bedroom, 21 cover classes are enough, but in the kitchen you should buy 23 grade.The highest indicator of this value may be 32.

Drawing and quality

Although everyone chooses the color and pattern options to his own taste and in accordance with the existing design in the room, one should pay attention to the quality of the flooring material. You should not buy rolls with the same part number from different batches, this is fraught with a color mismatch. Examining the roll when you purchase, you need to deploy it and examine for air bubbles, pores and tubercles. All this indicates a poor quality manufacturing process.

The color on the surface should be uniform without visible drops. Wiping in a new roll is an indicator of a thin protective film. Drawing on quality linoleum has the same clarity and shape.

Additional selection criteria

Although most linoleums have their own specific smell, it should not be so harsh that it is impossible to be in a room. You can check this only by inspecting the goods personally, and not by the Internet Another factor is the flammability of the material. In case of fire, ignited floors can cut the path to a single exit. Even during melting, substances toxic to respiration will be released, so it is worth buying products with a class G1 or G2 to residential and public places. For impassable premises, the lower class G4 is also suitable.

What linoleum choose

By systematizing most of the characteristics of this product, you can identify the main indicators for the specific use of linoleum:

1. Baseless material of 21 classes with 1 level of permeability will fit into personal cabinets and living rooms.

2. Kitchens and bathrooms will require PVC with a third level and 24 class or two-layer relin.

3. Children and bedrooms need a foam base and a layer of 3 mm. 22 classes and 2 levels will be enough.

4. Schools and hospitals, as well as office corridors, should be equipped with fabric types of bases with class 24 and 4. Thickness required 3.2 mm.

5. For allergy sufferers and children's camps with permanent residence, only natural linoleum is suitable.

How much is linoleum

The price of this flooring depends on the substances used in production and the parameters of thickness and durability. For common types of premises, linoleum will have the following price range:

- Natural material for asthmatics costs 1000-1900 rubles / m2.

- In a private office or hall coverage will cost 240-350 rubles per 1 square meter.

- For a children's room and a bedroom the price is 400-580 rubles / m2.

- In the bath and kitchen will need to buy material for 450-600 rubles / m2.

- Rooms with high traffic need a wear-resistant coating, which has a price of 580-680 rubles / m2.

It will be interesting to friends too