The design is designed to operate in conditions with a periodic or permanent presence of dust suspended in the air. The fan is used at agricultural enterprises to clean plant dust or move grain. Industrial workshops are ventilated to eliminate fine welding sludge, abrasive dust, metal or wood chips. The principle of operation is centrifugal. The body, for the most part, refers to the form of "snail". Material - non-ferrous alloys, steel, plastic and composites. Parameters for selection: power, speed, performance.

Content:

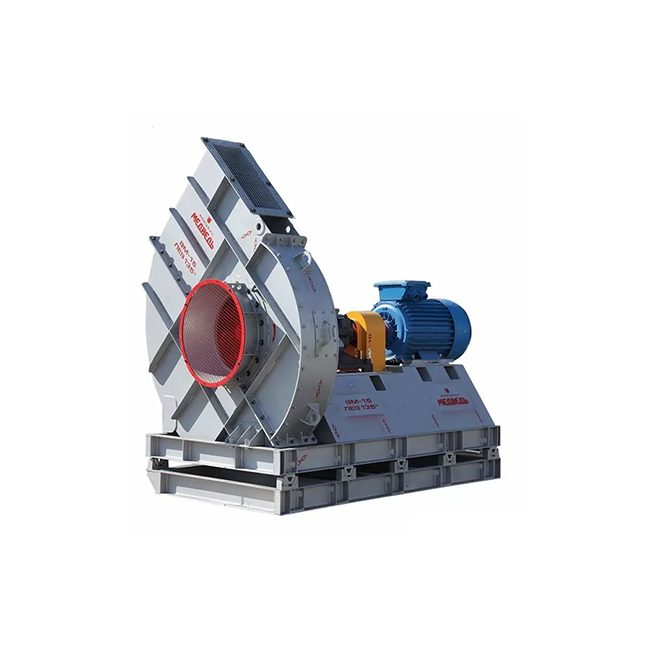

VM-15 - mill fan

It is intended for the formation of air transport movement of gas-air mixture with the content of non-aggressive coal dust.

The centrifugal complex is installed after the separator, cyclone. It is possible to use the unit in various fields of heavy raw materials or metallurgical industry in order to transport suspended non-aggressive mineral particles with a certain concentration.

The physico-technical properties of the suspension should be comparable to coal dust. The blades are folded back. Rotation - left or right. Applied unilateral absorption.

Pros:

- Performance, power.

- Steel case, blades with a protective anti-corrosion coating.

- The snail is designed to rotate up to 270 °.

Minuses:

- Negative traits are not marked.

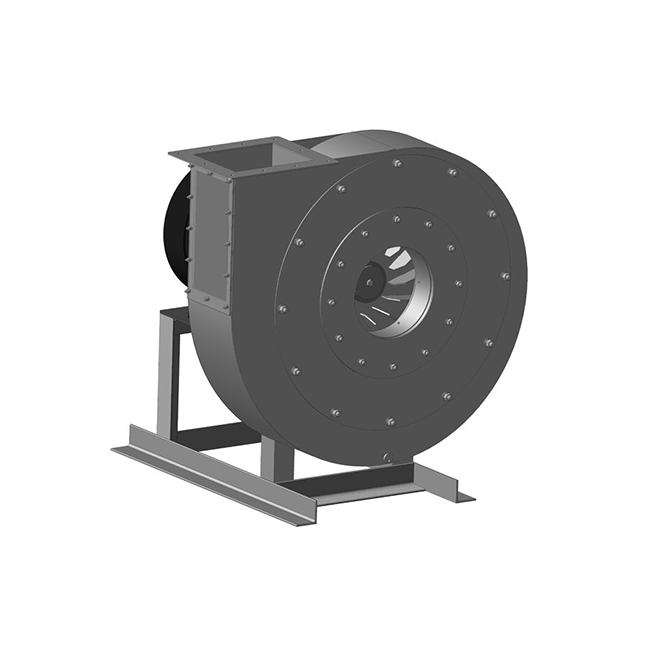

VTsP-3,15 - industrial, compact

Radial fan for operation in dusty industrial production. It is used to remove sawdust and small particles in the woodworking area, metal shavings, abrasive dust on metalworking lines.

Effectively copes with air purification in the welding area with the presence of gaseous products of combustion and sludge. Can be used in the pneumatic conveying system.

It is operated inside and outside the premises, taking into account the effects of precipitation and temperature changes. The optimal zone is a strip of temperate climate.

Pros:

- Sufficiently compact size, low weight for an industrial unit.

- Work with the air mixture containing abrasive particles, metal shavings.

- Successfully drives along the air line at the site of grain.

Minuses:

- Negative features of the product is not marked.

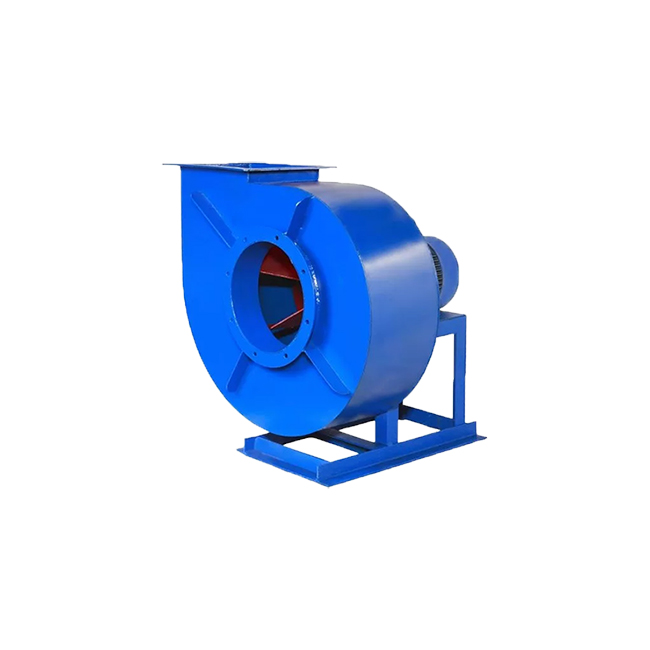

BP6-13-6,3 - high outlet pressure

Centrifugal fan with snail housing. Designed for ventilation of industrial areas of metalworking, welding. It can be used as a moving organ in the pneumatic transport system.

The unit can work in the gas-air environment in the chemical industry for the production of aggressive plant protective agents. The maximum working temperature reaches 80 ° C.

It is forbidden to transfer suspended matter containing particles of high stickiness, fibrous structure. The direction of rotation of the impeller is right or left. Number of backward curved blades 7 pcs.

Pros:

- It creates a very high outlet pressure, effective vibration isolators.

- The spiral-shaped rotating case, - convenience of installation, orientation of a stream.

- Work with slightly aggressive chemical medium from solid inclusions.

Minuses:

- Disadvantages are not marked.

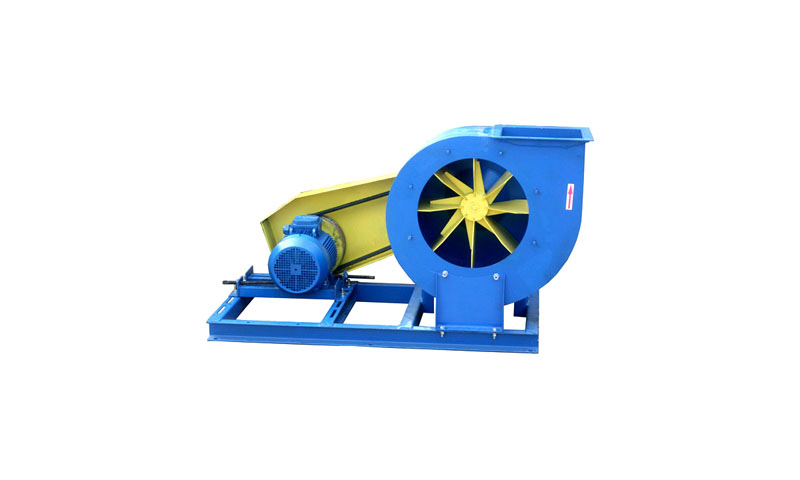

GRP 110-49-4 - V-belt transmission

Dusty radial fan with swivel helical casing "snail".Designed for joint operation in the system of industrial ventilation for the removal of dust-like products of woodworking, metal and abrasive dust from lines for cutting metal and chips from metalworking machines.

It is possible to use as an air pneumatic conveying for the movement of grain. The electric motor and the impeller are spaced apart, but mounted on a common power support frame. The transmission of torque is carried out by means of a V-belt transmission.

Pros:

- Universal application, successfully works in a dusty shop or pumps grain at a current.

- Simple installation, all units are united by one power frame.

- Swivel body with a certain pitch, steel elements.

Minuses:

- Disadvantages are not marked.

BP 140-40-2,5 - two versions

The design, which involves two variants of the impeller, is closed on both sides of the rim, or free, in the form of a separate impeller.

The first is used in industrial workshops to provide ventilation with the presence of solid inclusions: mineral or abrasive dust, wood, metal sawdust. The second is a suspension containing small amounts of fibrous material: wool, cotton, viscose or other threads.

It is possible to rotate the case at an angle of up to 315 °. Asynchronous motor powered by a three-phase network. The direction of rotation in both directions, depending on the purpose of the fan.

Pros:

- Two variant view of the impeller, allowing to expand the range of fan applications.

- Almost complete turn of the "snail".

- Acceptable performance level, low weight and size.

Minuses:

- Not marked.

Walter 5.5 - high speed

Centrifugal unit for operation in the gas-air transport systems for fine particulate matter and fibrous materials.

The main area of application: woodworking, furniture production, work with plastic, metalworking shops, chemical industry, agriculture. Operated as a separate ventilation device.

The working blades, in order to increase the corrosion and abrasion resistance, are made of high-strength steel. The radial fan favorably differs in a high-speed gas-air stream at the exit that provides the required productivity.

Pros:

- Build quality, excellent balancing of the motor and impeller.

- High-speed stream at the exit, straight, hurricane wind.

- Quality solid steel impeller.

Minuses:

- Only positive comments.

VTsP 7-40 No. 2.5 - universal application

The through passage, or the radial fan with the driving wheel located in the traditional "snail" case. Designed and used in various industries for the production of household or technical products. These are various air aspiration systems.

Transportation of grain agricultural products. Work on air exchange in the shops with the presence of fine sawdust, dust, volatile sludge. The fan works in the premises for the production of building binders, paints and varnishes.

Pros:

- A wide range of applications in various industries.

- Simple design, easy installation.

- Unpretentious, reliable.

Minuses:

- None.

It will be interesting to friends too